New Delhi [India], July 31: In India, waste doesn’t just pile up — it swallows space, suffocates cities, and silently poisons the land beneath our feet. Over 1.5 lakh tonnes of solid waste is generated every single day. From single-use plastic to discarded packaging, much of it ends up in landfills, rivers, or gets burned in open air. And while headlines chase global pledges and climate promises, true guardians of the environment don’t wait for applause — they take action.

In the heart of India, Rajratan Group has been quietly doing just that — serving as a Paryavaran Prahari, protecting the land with innovation, not noise.

Three Generations of Paryavaran Praharis

The story begins in 1973, in a small town in Madhya Pradesh.

While most people looked away from waste, Ratalalji Deepchandji Jain looked right at it — and saw raw potential. With no formal education or support, he began converting discarded plastic polybags into pipes for agriculture. It wasn’t for profit. It was about purpose.

By the 1990s, his son Ashok Kumar Jain expanded the work into water conservation, sustainable farming systems and started researching on “Multi Layered Plastic Waste”. By 2000, along with the next generation, by adding technology, R&D, and industry-grade applications PAC® Board was launched to replace plywood.

Three generations later, what stands is not just a company —

It’s a legacy of Paryavaran Praharis, each committed to turning waste into a weapon against environmental degradation.

Not a Slogan. A System That Changes Everything.

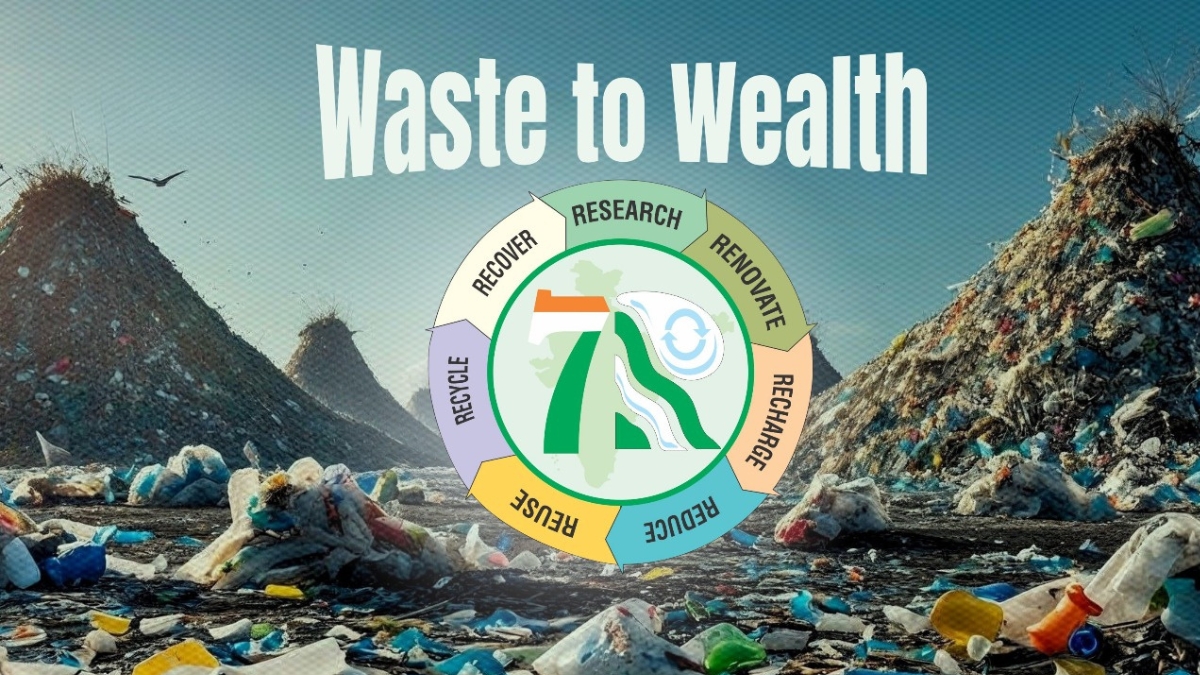

For Rajratan, waste was never the problem. The problem was what society failed to do with it. That belief gave birth to their 7R philosophy — a cycle built not in boardrooms, but through years of trial, error, and ground-level problem solving.

It begins with Research, understanding how to break down MLP and industrial plastic. Then comes Renovation, turning those scraps into raw materials. Every system is Recharged with efficiency — energy is optimized, inputs are reused, and operations are lean by design. Reduce, Reuse, Recycle, Recover — these aren’t just buzzwords. They practice everyday at Rajratan. From reusing offcuts to recovering heat and energy, nothing is wasted. Not effort. Not time. Not plastic. It’s not just about sustainability. It’s about designing failure out of the system — and making sure everything thrown away comes back stronger.

What We Build From Waste

Rajratan group doesn’t just recycle — it re-engineers waste into utility. Every product under the PAC® brand is a solution to two problems at once: what we throw away, and what we overconsume.

- PAC® Shuttering Boards – replace deforestation-heavy plywood in construction.

- PAC® Pallets – support building block plants — without touching a tree.

- PAC® Flight Cases – protect high-value cargo using recycled strength.

Every product is made from recovered MLP and pre-consumer plastic — serving as both a symbol and a solution. You’ll find them across India — in warehouses, schools, toilets, modular furniture, even airport runways. Where others see garbage, Rajratan sees groundwork.

When Waste Transforms Everything Around It

For every PAC® board that holds up a shuttering frame, for every pallet that moves a shipment, and for every modular toilet installed in a rural town — there’s a quiet offset happening behind the scenes. Because when Rajratan group uses a tonne of MLP waste, it’s not just avoiding a landfill. It’s avoiding emissions.

Over the past 25 years, this work has kept 22,000 metric tonnes of plastic from being burned or buried — waste that would’ve choked a drain, blackened the air, or leaked into the soil. Instead, that waste was transformed. And in doing so, it prevented over 44,000 tonnes of CO₂ from ever entering the atmosphere — the same climate impact as planting 20 lakh trees, or taking more than 21,000 cars off the road for good. It didn’t stop there. The energy saved from this switch is enough to power 40,000 Indian homes — carbon-free — for an entire year. And the oil that would’ve gone into virgin plastic? Rajratan group’s recycling methods have conserved more than 3.5 lakh barrels of crude. That’s thousands of tonnes of carbon that were never extracted, never processed, never burned.

If one tries to picture the volume — imagine 44 Olympic-sized swimming pools, not filled with water, but with plastic waste that now lives on as something useful. That’s the space Rajratan group has reclaimed — not just in landfills, but in how the country thinks about waste itself. This is not a symbolic win. It’s circular thinking, scaled — and working where it matters most.

Trusted by Institutions That Demand Resilience

Rajratan group’s work doesn’t just show up in shelves and shuttering frames — it’s embedded in the infrastructure of institutions that run this country.

When the Bank Note Press in Dewas needed a certified partner to manage hazardous printing ink and soiled currency, they turned to Rajratan group— and have trusted them since 2006.

When the Currency Note Press in Nasik required safe disposal systems, Rajratan group delivered.

When the Centre for Advanced Technology (CAT) needed planters and fencing solutions built from sustainable materials — they didn’t import. They went local, and they went green.

From supplying security huts for ESIC housing projects to building fabricated toilets for Simhast and under Swachh Bharat in MP, Rajratan group has shown that recycling doesn’t mean temporary — it means dependable.

And it’s not just the government. ITC, Nestlé, Hindustan Unilever, Patanjali and Essel Group rely on Rajratan group pre-consumer packaging waste and eco-product solutions. These are industries that move fast, operate at scale, and can’t pause for breakdowns. So, they don’t take chances.

Backed by an ISO 9001:2000 Quality Management System certification, Rajratan’s operations extend from R&D to finished product — converting not just plastic, but also metal foils, soiled packaging, and even misprinted currency into functional materials like Boards, Ropes, Pallets etc.

That’s not greenwashing. That’s green engineering.

And it’s why Rajratan group is officially recognized as a “GREEN PRODUCT INNOVATOR” user by ministries and agencies including:

- Ministry of Defence

- Ministry of Railways

- Ministry of Health and Family Welfare

- Ministry of Consumer Affairs

- India Post

- Indore Municipal Corporation

- IIM Indore

These collaborations weren’t won through pitch decks — they were earned, over time, by doing the hard work few are willing to take on.

Why They Do This — And What Comes Next

Rajratan Group wasn’t born to follow trends. It was built on the idea that waste is just a resource in the wrong place. Where others saw pollution, Rajratan saw raw material.

Where MLP was called non-recyclable, they figured it out.

Where sustainability became a marketing word, they made it a method.

And this story is far from over.

Their vision:

“An India with no landfills, where green products are the norm, not the niche.

Where waste workers become green ambassadors, and everyone — from government to industry — asks not “What can we throw away?” but “What can we reuse?”

This isn’t about noise.

This is about quiet, relentless work — the kind that changes more than policies ever could.

And for Rajratan Group,

The real work is just beginning.

If you have any objection to this press release content, kindly contact pr.error.rectification@gmail.com to notify us. We will respond and rectify the situation in the next 24 hours.